Jared Corry is the artist who designs and produces all of the knives and cutting tools for Self Reliance Essentials. He is a 34 year old North Carolinian who earned Manufacturing and Mechanical Engineering degrees from Oregon Institute of Technology.

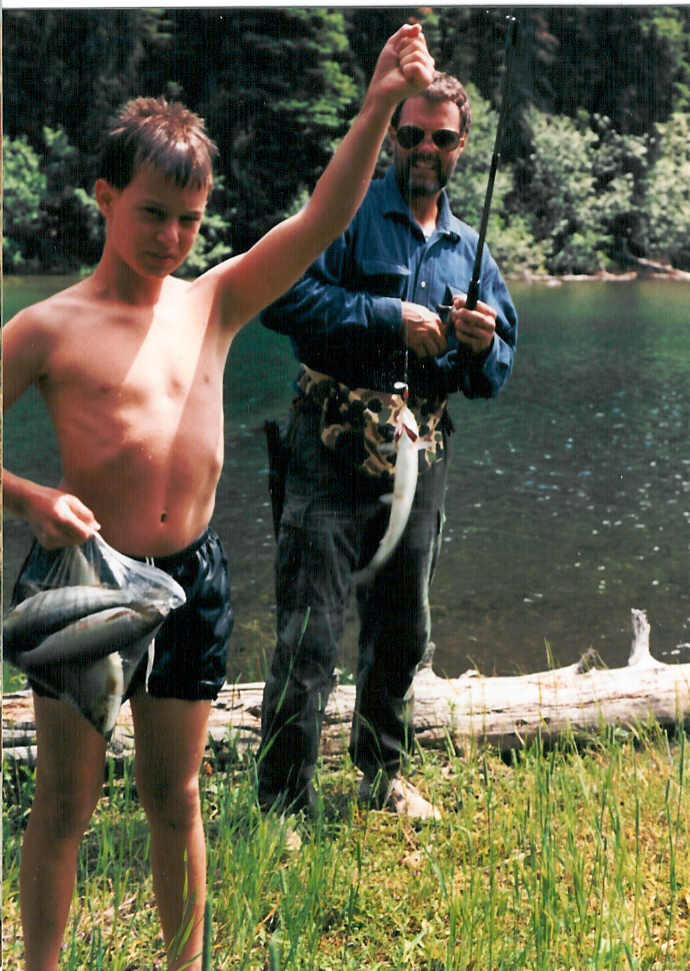

Jared’s experience as a knife maker began in 1994 when he bought a Green River scalping knife, and elk skinner bare blades from Cold Steel. With the help of his father, Chris Corry, he installed an ivory micarta handle on the scalping knife, and made a leather sheath as a Christmas gift for his uncle. In 1996, after sophomore year at a boarding school in Missouri, Jared’s family moved from North Carolina to Oregon. He met a knife maker named Eldon Coats, who volunteered his shop to Jared and his father in order to finish up a giant sword that Chris had started in the early 80’s, and the elk skinner Jared had left over from before.

The relationship between Jared and Eldon slowly grew over the next few years. Jared started his first real project from a scrap of 5/16” thick D2 that Eldon had left over from a very unusual and gigantic grape pruning tool. Using the stock removal method, and implementing a horizontal 6×48 belt sander, Jared (with a few fixes by Eldon) crafted his first knife, the Bolo Tanto. It is a clunky thing, but is finished well, and sits in a kitchen drawer at his aunt’s house.

After the Bolo Tanto, Jared continued designing and making various knives and sheaths throughout his high school and college years. His work kept getting better, and soon his artistry and execution became remarkable. Friends and family received many of these creations as gifts, and several were sold to friends who happened to have knife collecting tendencies.

After graduating from college, Jared was hired as an engineer at an optics manufacturing company in Bandon, Oregon. While living a simple, solitary life in an RV (borrowed from Eldon), Jared met master swordsmith Michael Bell of Dragonfly Forge, in Coquille, Oregon. Jared and Michael soon found that they had much in common, and a friendship was born. As an introduction to forging, Michael helped Jared hammer out a slender short sword from a piece of 1095.

Before long, Jared left his job in Oregon in order to fill a process engineering position at Barrett Firearms in Mufreesboro, Tennessee. There he learned some new manufacturing concepts, made some new friends, and got a grasp of what one well-known product can do in a receptive market.

Unsatisfied with a desk job, Jared left Barrett to spend a summer as Assistant Maintenance Director at his childhood summer camp in the Ozarks. From that point on, family projects consumed his attention and Self Reliance Essentials Inc. was born as a family business to provide an outlet for sales, manufacturing and construction efforts of both father and son. The Anubis tomahawk was to be the initial capital building project for the company. All the current knife designs were brought to be in order to use the remaining sheet material left after the tomahawks were nested in the laser cutting program.

As a carpenter, landscaper, outdoorsman, weapon enthusiast, and agriculturalist, Jared has used cutting tools since age 3 when his father gave him his first handmade knife.

During the learning phase of knife making, Jared can’t remember any particular inspiration or specific function for his work. Perhaps it was merely an example of the zen that comes with manual labor. His experiments with many styles and design intent simply laid the ground work for his current undertakings. Jared’s inspiration as a designer begins with his innate need to be practical, efficient, organized and effective in all tasks; his problem solving persona has driven him to create knives and tools that are truly multi-functional. They are constructed with purpose, artistry, and caring. Materials are also selected as a matter of practicality. 1095 carbon steel, and phenolic composites have a long history of use in the custom knife world, and have proven their serviceability. Modern stainless steels have some notable advantages when selected for smaller knives, but for big choppers and fighters, material cost becomes a significant issue.

Jared’s personal brand has progressed through the years. Early blades were marked CORRY with two swords crossing through the O. Now, he has coined Omnivore Blade-Works as his personal brand.